JINPAT Electronics is a historical slip ring manufacturer with great innovative ability. Since establishment, JINPAT has devoted into perfecting slip rings for various purposes. With a strong and inde...

Menu

Every year JINPAT invests 15%-20% of its profit into doing research&development. There are about 100 experienced engineers in the R&D team.

JINPAT slip rings can satisfy military demands in high protection grade, explosion-proof and shock proof, representing high-tech capacity.

JINPAT has already acquired 60 international certificates and qualifications. JINPAT establishes itself for its independent R&D ability

ABOUT US

We understand military and defense equipment manufacturers require the ultimate in product design, verification and testing.

* Customer non-disclosure management.

* National Confidentiality Ⅲ Certified.

* Annual online customer satisfactory research and action.

* Customer visit every year for after-sales and satisfactory research.

* Sales service responding in 12 hours.

* Dedicated account manager.

* Online technical support.

* On- site support by agents or representatives.

* Free design solution.

* Support factory evaluation.

OUR VIDEO

NEW PRODUCTS

OUR CASE

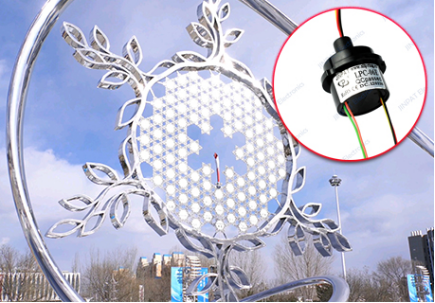

JINPAT Electronics is a historical slip ring manufacturer with great innovative ability. Since establishment, JINPAT has devoted into perfecting slip rings for various purposes.

OUR NEWS

The computer DIY market has a certain scale, but its industry has almost no relevance to the slip ring industry. After all, computer motherboards, CPUs,

OPTOELECTRONICS leads the future and drives application innovation! THE 25TH CHINA INTERNATIONAL OPTOELECTRONIC EXPOSITION will be held at the Shenzhen Word Exhibition and Convention Center from September 11th to 13th! JINPAT

Oil and gas exploration equipment is an important part of China’s high-end equipment manufacturing industry. At the same time, slip rings are also installed in

In modern aerospace engineering, ensuring the safe operation of equipment is of vital importance. Recently, China’s commercial aerospace sector has once again become the focus

The application of JINPAT slip ring in projectors is mainly reflected in its unique performance and technical characteristics, which can ensure the uninterrupted transmission of

The 2024 Paris Olympics is about to be held, and there will be an opening ceremony that will attract worldwide attention. In previous Olympic opening

Copyright @ 2021. JINPAT . All rights reserved.