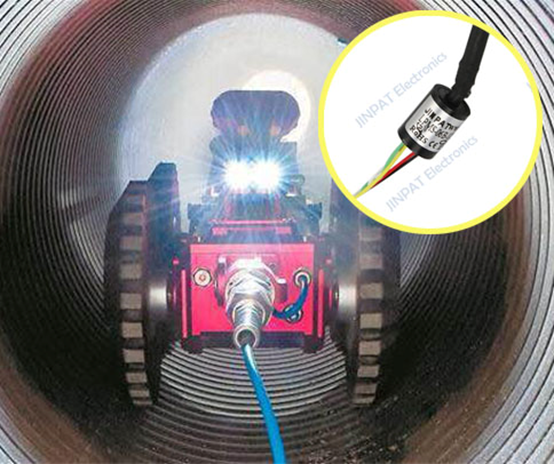

Pipelines carry the mission of everyday passing of medium or that in the industrial scene. You will notice the importance of the underground sewer systems when it is raining heavily. The sewer systems have to been maintained regularly to fulfill a healthy operation. The same is true for pipeline systems that operate to transmit various kinds of medium. A regular-based inspection is needed. For pipes with large diameter, it would not be a problem for human to enter, but for safety concern and those with smaller space, robots are introduced to carry the job. Pipeline robots are artificial intelligent devices that can enter the pipelines with ease and inspect the inner circumstances of the pipeline. Slip rings are necessary component to allow an agile movement of the pipeline robot joints while transmitting power and signals. JINPAT Electronics as a professional slip ring manufacturer, provides slip ring solutions for pipeline robots.

For pipeline robots that work in limiting space, JINPAT Electronics recommend LPC capsule slip rings, LPM miniature slip rings and LPMS super miniature slip rings. To move freely in a pipeline, the figure of the inspection robot is strictly restricted. That is to say slip rings should be tiny in size to fit in the related pipeline robots. JINPAT LPC, LPM and LPMS are very small in size and light in weight. LPMS-06B-06S is a very typical slip ring model designed for the pipeline robots. With a diameter of 8.5mm and a length of 14.2mm, this super miniature slip ring can fit in limiting installation space. It is a 6-channel product with 2 signal channels, 2 analog channels and the left 2 channels for other signals. Generally speaking, the slip rings are installed to allow the camera and the joints of the robot to rotate. And to allow a more vivid graphic transmission, sometimes SDI and HDMI integration is necessary.

As for pipeline robots with larger size and more complex movements, slip rings are expected to be fit to allow higher power capacity and more diverse functioning, which usually leads to choosing slip rings with larger size. Through bore slip rings are a favored choice for the easy installation on robot shaft and their flexibility in integration. Especially for pipeline robots that not only see through the condition of pipeline but also shoulder the mission of repairing, accurate and robust joint movements are demanded. JINPAT through bore slip rings are able to provide an accurate and dynamic rotation while maintaining a reliable data transmission. The through bore design also provide great possibility for further integration with other slip rings.

Contact JINPAT Electronics for details of our slip ring and rotary joint products, we also provide free consultations of custom design.