The rapid development of high-speed rail has brought convenience to people’s travel and made significant contributions to economic development. Its smooth operation relies on complex and critical inspection systems. In this system, the seemingly tiny component, the slip ring, plays an indispensable role. As an important component of high-speed rail inspection equipment, the function of the slip ring extends beyond just power and signal transmission; it also encompasses monitoring of various vehicle parameters and data transmission.

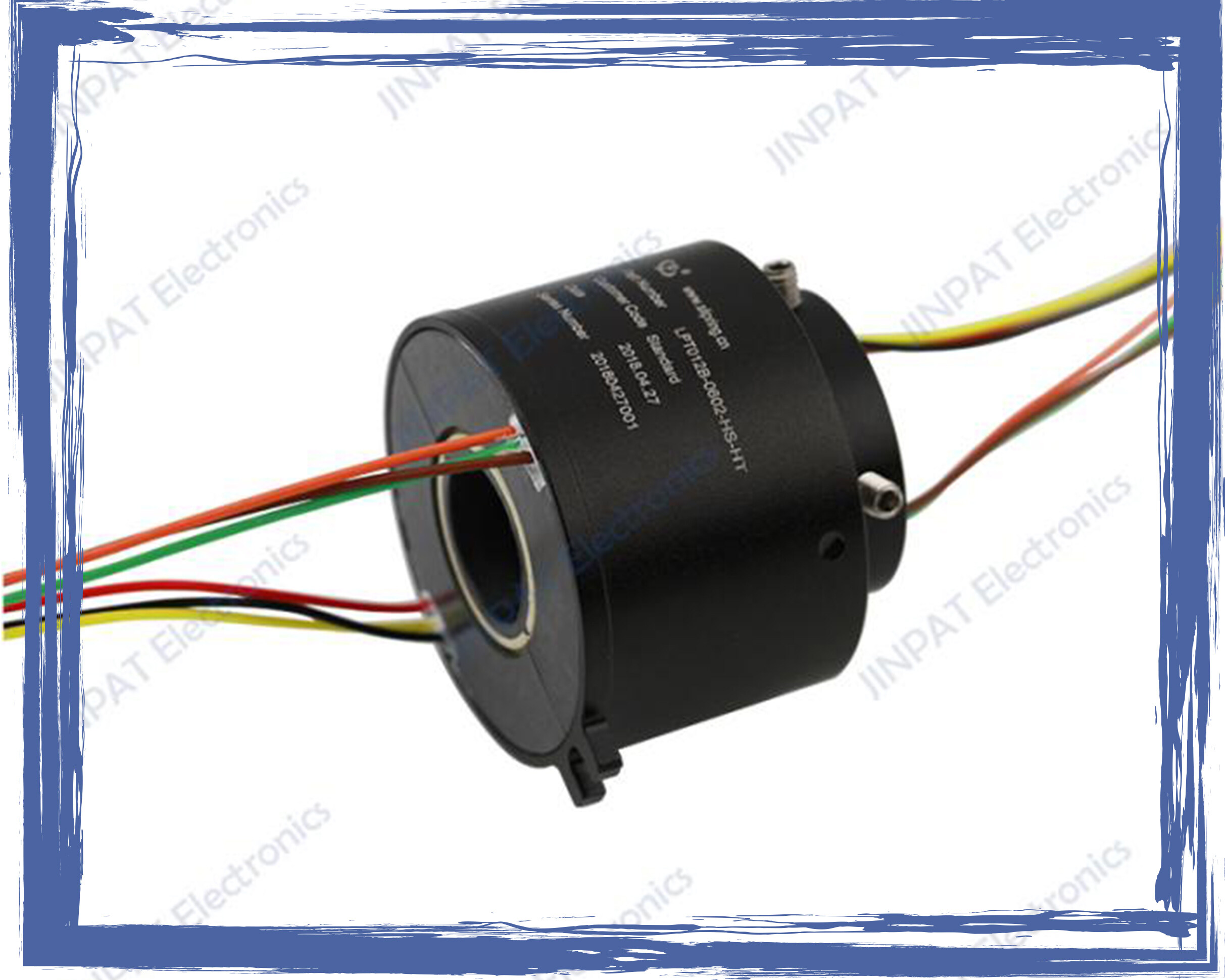

As a well-established international manufacturer of slip rings, JINPAT has developed numerous slip ring products for high-speed rail inspection equipment. Among them, the LPT012B-0602-HSstands out as a representative product. JINPAT fully considers the high-speed nature of high-speed rail equipment during operation. To ensure stable and reliable operation under various complex conditions, the LPT012B-0602-HS can achieve a working speed of up to 2000 revolutions per minute. It also utilizes wear-resistant materials and advanced sealing designs for durability and longevity. This ensures that high-speed rail equipment can maintain stability during prolonged operation, reducing maintenance frequency and lowering the operating costs of high-speed rail inspection equipment. Furthermore, this slip ring adopts a compact design, allowing for flexible installation in limited space. This is crucial for high-speed rail inspection equipment, especially when space for various vehicle components is limited, ensuring effective integration and use of the slip ring. These features make the LPT012B-0602-HS an ideal choice for high-speed rail inspection equipment, meeting multiple technical requirements under conditions of high-speed operation, prolonged usage, and limited space. Its performance advantages greatly enhance the overall system reliability.

With the operation of JINPAT’ dedicated slip rings for high-speed rail, the monitoring system can obtain real-time critical data such as the train’s operation status, temperature, and vibration,providing comprehensive and timely information to operators. This not only helps in timely detection of potential issues and early maintenance to ensure the safe operation of high-speed rail but also provides strong support for operational optimization.